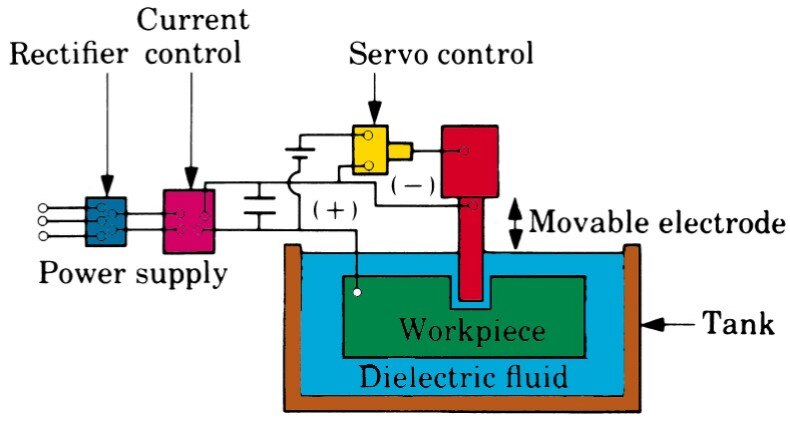

The principle of electric discharge machining.

When using EDM, the electrode and the work piece are respectively connected to the two poles of the pulse power source and immersed in the working fluid. The servo feed system will control the feed of electrode accurately and automatically, when the gap between the electrode and work piece reaches a certain distance, the pulse voltage applied on the electrode breaks down the working fluid to generate a spark discharge. At the moment of discharge, the arc generates a sharp high temperature accompanied by a change in pressure, so that the metal material at that point is immediately melted, vaporized, and exploded into the working fluid, then condensed into solid small particles which will be washed away by the working fluid. At this time, the metal surface is eroded to a pit, the discharge is stopped, and the working fluid is restored to the insulation state, and then the next pulse voltage is continued to discharge, and repeat the process. Although there are few metals that are eroded by each pulse, there are thousands of pulse discharges per second, which can quickly erode the metal to achieve a certain productivity. Under the condition of maintaining a constant discharge gap between the electrode and the work piece, the electrode will automatically feed the work piece continuously while the work piece is eroded. Finally, the shape corresponding to the electrode is done.

Post time: 08-20-2019