Complete Collection of Broken Bolt Removal Method 2019

For vast majority of the mechanical industry compatriots, it will be very lucky if you see this article! Because you may have encountered with broken bolts or taps in the work-piece. Here we collect some very practical methods for you.

1. Broken Bolts Removal with Chisel

Before processing, first clean impurities around broken bolts, then use a small pivot-end chisel to slowly tap along the tangential direction of the thread to remove broken bolt.

This method is suitable for bolts whose head is higher than the surface of the work-piece and has no rust.

2. Broken Bolts Removal by Tapping

Before processing, firstly smooth the head of broken bolt, drill a small hole in the middle of broken bolt with a smaller drill bit, and then take a drill bit smaller than the broken bolt to gradually expand the hole. When the reaming size is in contact with the thread size, tap thread with the tap which is the same thread of broken bolt; a drill bit larger than the diameter of the broken bolt can be selected, the hole is reamed in the middle of broken bolt, and the tapping is repeated, then broken bolt is replaced by the enlarged bolt.

This method is suitable for rust bolts or where the requirements for threaded holes are not strict.

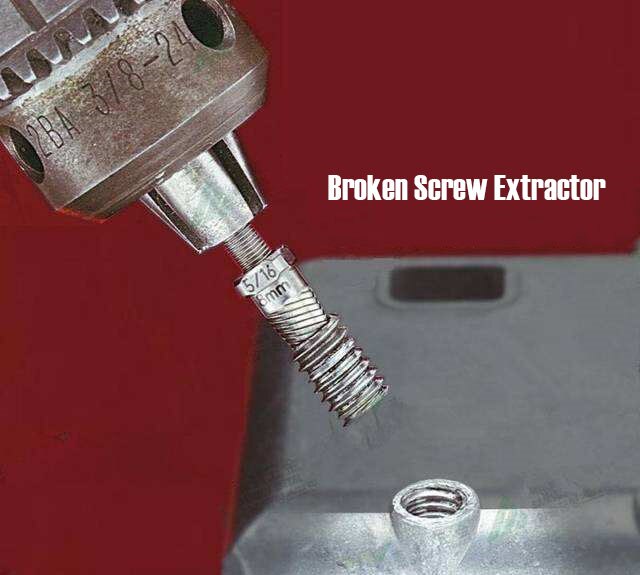

3. Broken Bolt Extractor

Before processing, firstly smooth the head of the broken bolt, use a pair of tweezers to pry a pin hole in the middle of the bolt, and drill hole with a drill bit smaller than 2~3mm diameter of the thread. After drilling to a certain depth, use the broken screw extractor to tap inside hole in reverse, then unscrew the broken bolt with a wrench.

This method is suitable for most broken bolts scenarios.

4. Broken Bolt Removal by Welding

If the broken bolt is higher than the plane of working piece, the old nut larger than the diameter of the screw can be welded to the screw, and then the broken bolt can be screwed out with a wrench. If the broken screw is relatively large and is broken off from the surface of the work-piece, a nut smaller than the broken screw may be welded to the broken screw, and then screw out the broken bolts with a wrench.

This method is suitable for bolts which is difficult to rust and remove.

5. EDM Broken Tap Removal Machine

If the broken bolt is lower than the plane of the work-piece, or the case with the traditional method not to solve, portable EDM broken tap remover can be used. Using the principle of spark discharge, a hexagonal counter-bore or a groove is machined in the middle of broken bolt with an electrode smaller than the diameter of broken bolt. Then use a hexagonal wrench or a screwdriver to screw it out.

Post time: 09-26-2019