Cutting Fluid Daily Maintenance Tips(1)

"Seven Points Usage for Three Points of Product". We should make full use of product to achieve better economic benefits despite the product is quality. If the workshop’s front-line production personnel possess of good basic knowledge and experience, the production can gain unexpected benefits without using high price products. The usage and routine maintenance of cutting fluid shows a very good example.

Daily Maintenance Management Tips:

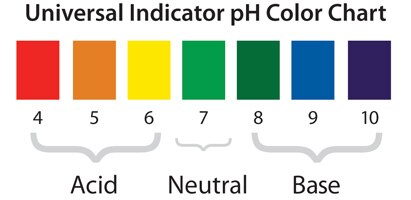

1. Regularly check the concentration and PH value of the cutting fluid. Dilute the cutting fluid with quality tap water, stir and mix well after reaching the specified concentration, and keep the PH Value between 8.5 and 9.0. When the PH value is found to decrease, PH enhancer (such as sodium carbonate) should be added.

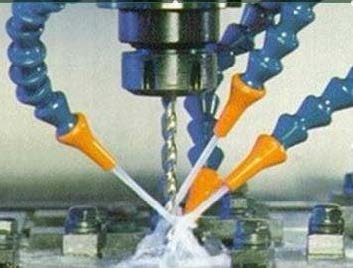

2. Make sure that the cutting fluid pipe is unblocked and the metal powder is removed in time. In metal processing, the pipe is easily blocked by various metal powders. If not removing, they will not only affect cutting but also seriously pollute cutting fluid.

3. The contaminated cutting fluid should be strictly cleaned. Generally, the surface of cutting fluid after contamination is mixed with rail oil and metal powder, which will cause the lack of oxygen inside the cutting fluid, and the anaerobic bacteria breeds a lot, making the cutting fluid deteriorate and smell. To avoid it, an industrial oil-water separator can be used to separate rail oil and metal powder to keep the cutting fluid pure. SUN-01 oil-water separator can effectively solve the problem of smell of cutting fluid. ONLY USE FOR 1 HOUR EVERY DAY, 1 KWH PER MONTH, NO AFRAID OF IRON FILINGS, LONG-TERM OPERATION WITH MAINTENANCE-FREE.

To be continued…

Post time: 09-05-2019