Selection of electrode size and usage of special electrode

-

The discharge area of the electrode is generally about 0.3 larger than its own diameter. For example, if the electrode diameter is 3mm, the processed hole diameter is about 3.3mm. When selecting the electrode, please consider the electrode discharge area, and choose the suitable size to avoid any damage to the thread.

-

Please refer to the below table for electrode size selection when taking broken tools.

|

Broken Tool |

Size |

Electrode Size |

Note |

|

Tap |

M3 |

Φ1.5 |

Keep the electrode as short as possible, reduce jitter |

|

Tap |

M4 |

Φ2.0 |

|

|

Tap |

M6 |

Φ3.0 |

|

|

Tap |

M8 |

Φ4.0 |

|

|

Tap |

M10 |

Φ5.0 |

|

|

Tap |

M12 |

Φ6.0 |

|

|

Tap |

M14 |

7×2 |

Sheet electrode |

|

Tap |

M16 |

8×2 |

|

|

Tap |

M20~30 |

10×2 Sheet electrode |

Taps above M20 can be processed in stages |

Electrode size selection table

-

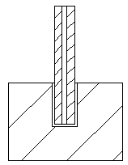

If you want to punch holes (Ø1-Ø3), you can use hollow electrodes, as the picture shows:

-

When the hollow electrode is used, the working fluid can enter from the inside and the iron filings are directly flushed away, which avoids the difficulty of external water flow entering and accelerates the drilling efficiency.

Hollow Electrode

-

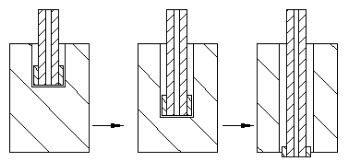

When processing deep groove or deep hole, high-efficiency perforating electrodes can be selected, as shown in the figure:

High-efficiency Perforating Electrodes

-

The electrode is hollow with a large head diameter. The internal water inflow can well discharge the iron filings and avoid the clogging of debris; the diameter of the head is larger than the electrode body which increases the gap between the electrode and the workpiece, reduces the side discharge loss, and also increases the drainage speed.

-

In addition, electrodes with different cross-sections can be used to process holes of different shapes.

Post time: 11-30-2019